Most industrial plant operators are embracing the robotic technology. The use of robots in production has brought enormous success to companies. The robotic machine tending comes with a cost.

Consider the following reasons for investing in robotic machine tending

1. They Occur in Various Sizes and Shapes

The robotic machine tending is available in different sizes and shapes. There are small robotic tending machines which can be used in small shops. The little robots are offered at an affordable price, which caters to the low shop minimum budget. The robotic machines also have natural and straightforward programs that can be used to accomplish small tasks.

The robotic machine tending is available in different sizes and shapes. There are small robotic tending machines which can be used in small shops. The little robots are offered at an affordable price, which caters to the low shop minimum budget. The robotic machines also have natural and straightforward programs that can be used to accomplish small tasks.

There is a bigger robotic machine tending for big industrial plants. The robots differ in complexity, depending on the tasks they are required to perform. Bigger robots are needed for big volume production.

There are a variety of robots depending on the size of the production. Most of the machines tending robots have a small footprint, which saves on space. Some have small models that fit in a machine tool.

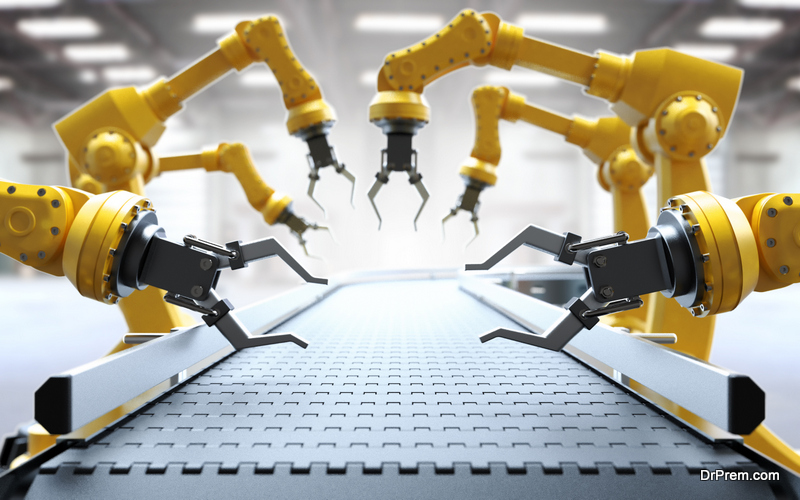

2. The Robotic Machine Tending Are Flexible

The robots are equipped with adjustable arms. The flexibility of the robot s enables it to perform various tasks. The robots can be adjusted to carry and grip objects of different sizes and purposes. Robotic vending machines can easily handle objects which are very small to be processed by humans.

The flexibility of the robots makes them easy to program. Robotic machine tending can be programmed and reprogrammed to suit the needs of the user. The applications used in robots are not complex. Anybody who has the knowhow can work with them.

3. They Are Automated

The robotic machine tending is automated and hence does not require human input. The robots are pre-programmed to perform various tasks. They are capable of changing from one task to the other without relying on human command.

The robotic machine tending is automated and hence does not require human input. The robots are pre-programmed to perform various tasks. They are capable of changing from one task to the other without relying on human command.

Most of the have vision systems that enable them to detect any change in material. The robots can also load and unload materials in a machine non- stop. The robotic tending machines can identify the end of a process and can start a new process.

4. They Are Customized

The robotic machine tending is made in a way that one can build their custom cell. The collaborative robot can be used to create a cell that custom fit in a given. It is possible to hand-guide a program that makes it easy for the robots to be integrated into a system.

5. They Come with an Integration Kit

The robot manufacturers are giving an offer of a pre-engineered integration kit. The collaborative robot arm has a package that contains everything that is needed in robotic machine tending. The machine tending cells are already programmed to fit the given operations. The integration kit and the operating systems do not have an additional cost.

The robot manufacturers are giving an offer of a pre-engineered integration kit. The collaborative robot arm has a package that contains everything that is needed in robotic machine tending. The machine tending cells are already programmed to fit the given operations. The integration kit and the operating systems do not have an additional cost.

6. Robotic Machine Tending Is Not Expensive

Most people think that the robotic machine tending is costly. Robotic machine tending is less expensive and is viable for small productions. The robotic machine tending can be used for tedious and dangerous work that will require more workforces hence reducing the cost.

The machines are easy to use and can be called upon any time they are needed. The automated process makes the production less expensive compared to production, which is done manually.

Conclusion

Robotic tending machine provides the solution to challenges of loading and unloading of raw materials in a tool. The robotic systems are not complicated and can be used in any form of production. Robotic machine tending performs different tasks using a single application. The end products from robotic machine tending are of high quality. Thus, the manufacturing plants that use the robotic machine tending are assured of class, which translates to success.

Article Submitted By Community Writer