Kinetic Energy Recovery Systems also known as KERS are automotive systems in which a moving vehicleâs kinetic energy is recovered when we apply brake and this energy is stored in a battery for later use. The KERS was first use in Formula One cars in 2009 racing season. Many companies are developing this high-performance system for conventional vehicles. In 2010, the Formula One authorities stopped the use of KERS but they readopted it in 2011.

A total of 9 Formula One teams used KERS in 2011 season, while 3 teams preferred not to use it. The major reason behind not using the KERS was because the pack which is used to store energy weighs 25 kilograms. Though, this pack did not add to the weight of the car by much, it increases the center of gravity of the car which led to penalty. The KERS concept is the brainchild of physicist Richard Feynman. Currently we know about 2 types of KERS system: one is electrical by battery and another is mechanical by flywheel.

The good

KERS uses waste heat to generate energy

Description

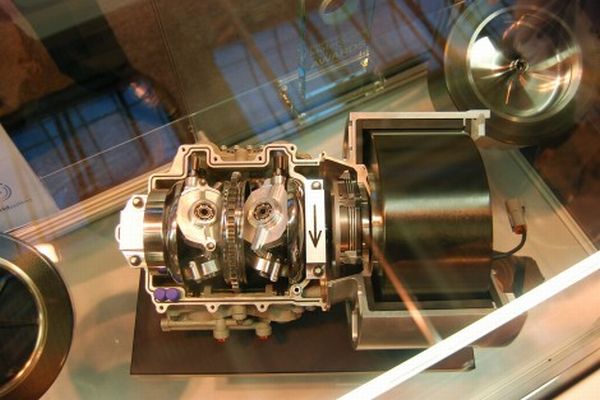

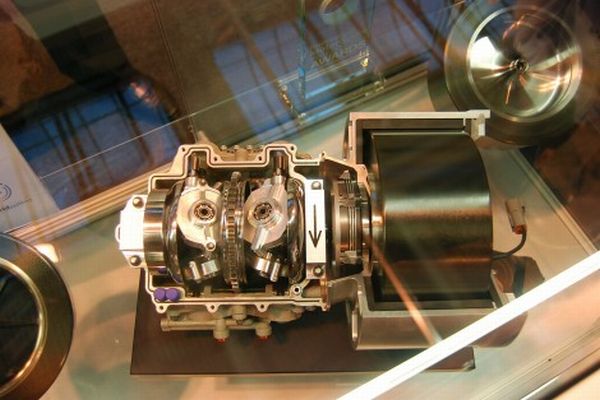

The kinetic energy present in the waste heat is recovered by the KERS and then used for accelerating the car. The waste heat recovered by KERS is produced by the braking process of the car. The KERSâs CVT portion is called âvariatorâ and its mechanical efficiency is as much as 90 percent. The KERS used in Formula One cars involves no battery, which means drivers are more safer and the weight of the car also does not increase too much. The KERS of Formula One is environmentally friendly as well because it does not involve lithium-based batteries, which are toxic in nature. It is expected that this system will soon used in the consumer vehicles because the flywheel-based nature of the KERS is a perfect thing to be used for stop-and-go traffic.

The bad

The two major drawbacks of the KERS are storage capacity and regenerative brakes used in the cars.

According to the current regulations, the KERS can convey a total of around 80bhp or 60KW and the storage capacity of this system cannot be more than 400 kilojoules, which is quite low. The storage capacity of 400KJ is not sufficient enough to allow KERS emerge as a fantastic alternative and more research is needed to improve the capacity if we want to use KERS as an alternative in future. The major drawback of regenerative brakes is its high maintenance cost and the need to match the generated current closely with the supply characteristics. The need is to control the voltage perfectly.

Can this be avoided?

More research is needed to develop KERS technology, so that it can became a viable alternative. KERS is an eco friendly technology and the Formula One teams are using this technology to make the sport more fuel efficient. The introduction of KERS in road cars would promote eco friendly practices. This technology should be promoted because it is making use of the heat which normally goes waste. The use of waste heat to generate energy is without doubt a novel concept.

The ugly

The KERS is currently used in race cars only.

Currently only cars used in Formula One racing are using KERS and automakers are still not showing interest in using this high-performance eco friendly technology in commercial vehicles. The KERS will become a viable alternative only when the automakers will start using it road cars. It is high time that the automakers should move ahead and manufacture some cars using this technology. The major weakness of the KERS technology is the storage capacity and regenerative braking system and these are preventing car makers from trying out this technology in vehicles used for normal transportation.

The Bottomline

The KERS is without doubt an efficient technology which has the potential to emerge as a viable alternative in future but it has some weaknesses as well.