Making green products can never be equivalent to becoming a complete green package unless packaging complements the item. But how do you integrate green products with green packaging? The way out of this problem is not only by using recyclable material for packaging but also making the package more compact and snug. It should also be able to withstand handling and transportation. Big brands as well as smaller names in the manufacturing industry are coming up with innovative ideas to meet the green tag. Check out some of these cool packaging techniques.

1. Method’s small detergent bottle

Method laundry detergent comes packaged in a bottle that controls the amount of detergent that will ooze out with each pump. Also, the concentration of the detergent is 8x in comparison to other regular detergents that have 2x concentration. Therefore, a small bottle comes loaded with higher value. The packaging is made from recycled material HDPE (identified by the resin code #2).

2. Amazon’s frustration-free packaging

Online retailer, Amazon, after deliberating with various companies, has come up with the frustration-free packaging concept which uses lesser materials and is very easy to open. Cardboard is used as the packaging material. In 2008, 19 products adhered to this system of packaging and now over 300 use the same.

3. Arm & Hammer’s refill bottles

No more in production, this was truly an innovative idea that could have worked wonders. An empty dispenser with a bottle of cleansing concentrate was sold. The concentrate was to be mixed with water and then used. Each bottle could be used seven times, hence, was very economical. The packaging material was very light and convenient for shipping.

4. Plant-based plastics

Bioplastic is the new material that is highly sought after by packaging companies. Sun Chips are known to have pioneered the use of bioplastic. The company used corn-based polylatic acid to make its chips packets. Yerba mate maker, Guayaki, meanwhile, uses wood pulp for its product packaging.

5. Non-foam cushioning

Styrofoam, a recyclable and expanded polystyrene foam making company, is facing competition from non-petroleum based packaging materials as they are more eco-friendly. Dell is offering a bamboo packing for a few of its models. This packaging is non-petroleum in nature and is compostable. And since foam recycling is not so common, bamboo packaging is a way better solution.

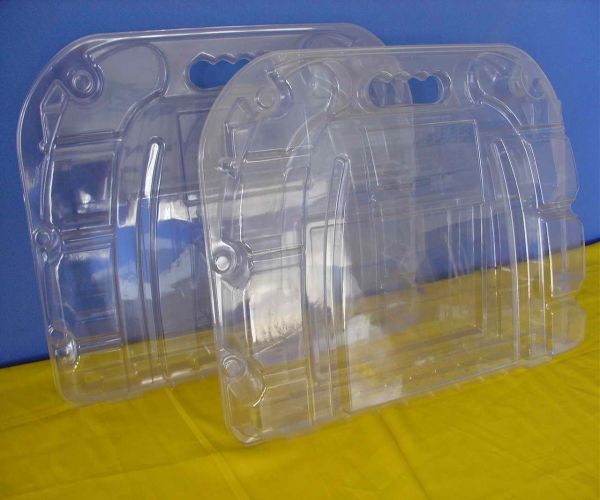

6. Clam-shell alternatives

Clamshells are generally made from PVC which is not a recyclable material. Hard to open and a bulky constituency make it not so popular with consumers as well. MeadWeatvaco, CardPak and Winterborne are a few companies that have displaced clamshells with alternatives that use much less percentage of PVC and can be recycled easily. Though this type of packaging is not a complete solution to the PVC problem as it is only a substitute that occupies lesser space and sticks more snugly to the product, it does trump using clamshells. A paper board is used to hold the shell in place.

7. HP’s boxless laptop

In 2008, HP initiated a new movement by packaging its laptops in bags which took 97% less packaging materials and space in comparison to conventional packaging. These laptops were sold only through Wal-Mart and Samâs Club outlets. Multiple bags were packed in large boxes and then shipped across different places. The material used for the bags was 100 percent recyclable, saving not only shipment space but also contributing to the green tag.